Services

Consultancy

Research projects, national and international

Tasmanian minor species identification and uses

Milling and drying Tasmanian minor species

Design for manufacture

Plantation Eucalypt species, product development

Milling and drying plantation eucalypt

Timber Adhesives traditional and non toxic

Steam bending

Veneering methods

Thermal modification of timber

High value uses for plantation Eucalypts, nitens and globulus

Non toxic timber adhesives

Lamination processes to improve strength

Steam bending non traditional materials

Manufacture of veneered products (ply and LVL)

Research documentation, preparing reports and literature reviews to meet clients needs

Commissions

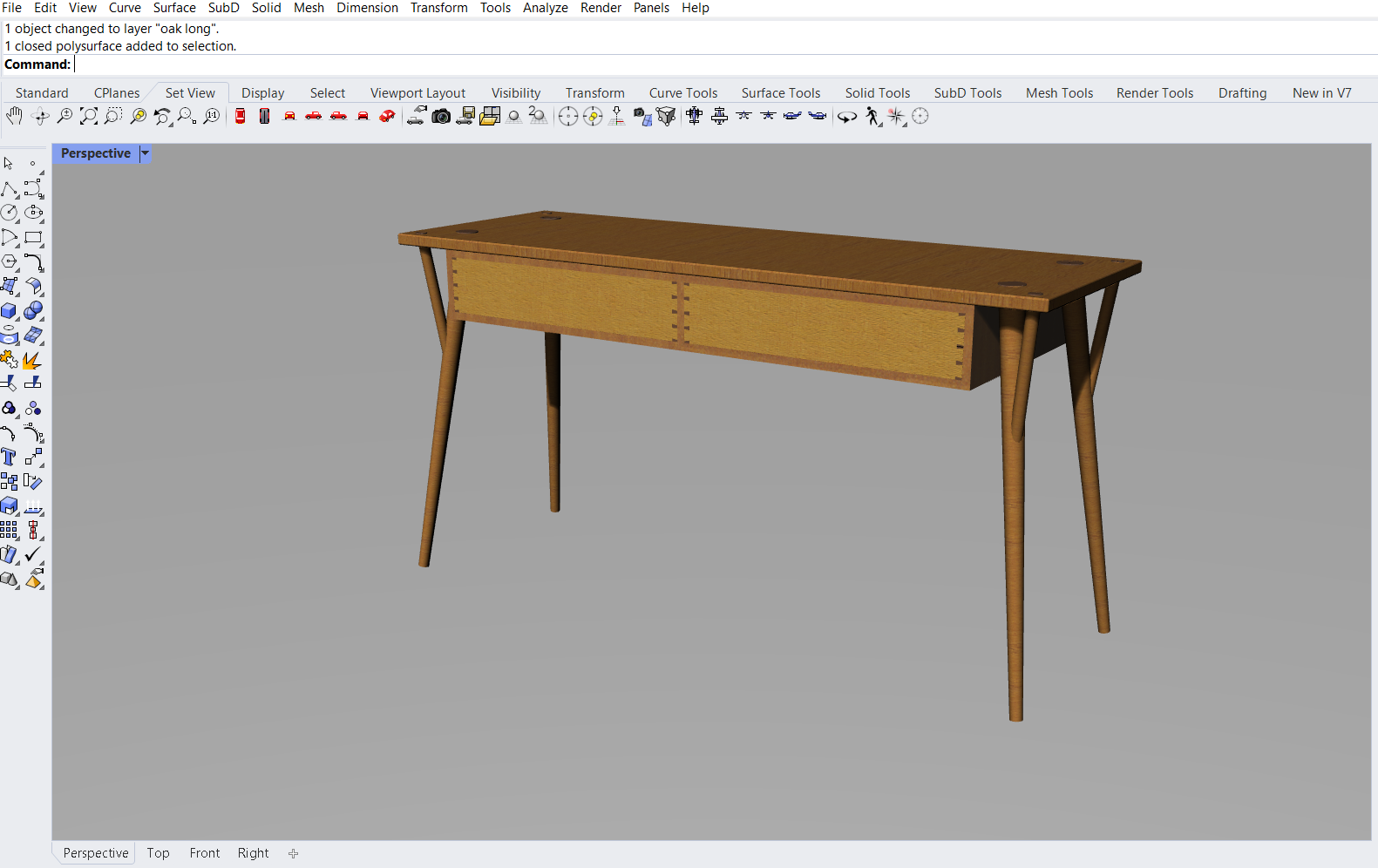

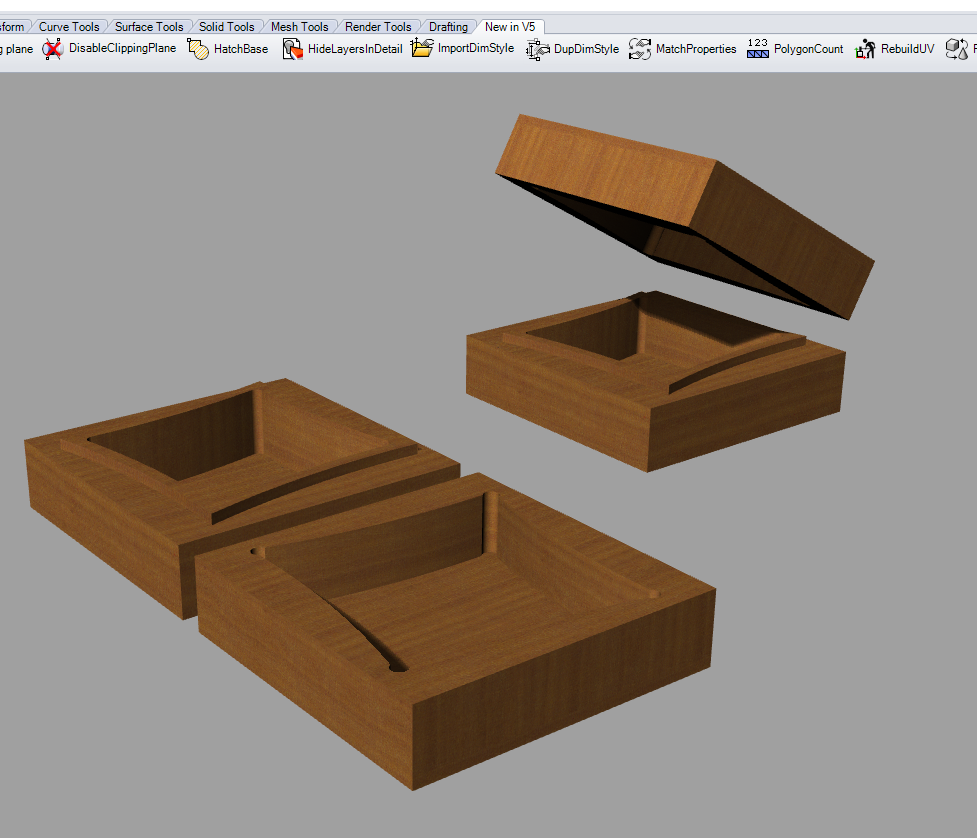

Design for manufacture

Sketch through to production

Freestanding and inbuilt commissions

Furniture

Large scale interior fitouts

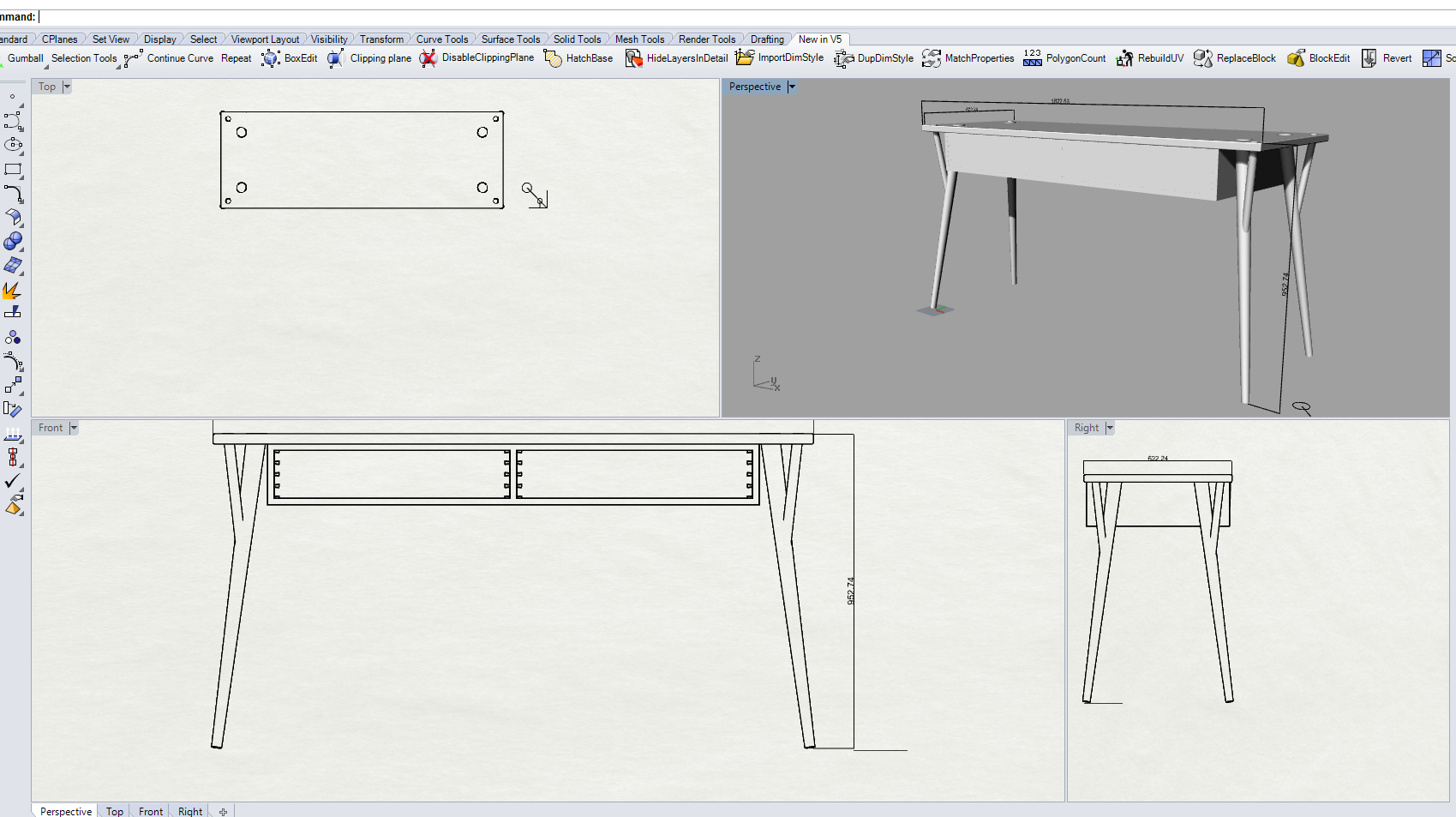

CAD Design and drafting

CAD modelling

Packages used Rhino, Autocad

3D modelling

CAD design for production

3D scanning and cloud data manipulation

Research and innovation

Vacuum pressing equipment

Steam generators

Thermal Modification processes including development of equipment

Designing for specific manufacturers

Designing jigs for production

Test chamber

Thermal modification, experiments to determine the suitability of Tasmanian timbers to be processed. This prototype was made to test the various methods to determine the most suitable to take into production scale. These tests proved that Tasmanian and plantation species were capable of being processed.

Plantation Eucalypt, thermal modification experiments

The differing colours represent the temperatures the samples have been heated to. The range is from top with no treatment to bottom at the highest temperature possible. In European this process has proved significant in reducing expansion and contraction of timber. From these tests the normal range in this eucalypt species of .7% summer to winter reduced to .2% expansion and contraction. This process reduces degrade in external applications by eliminating fungal attack and reducing penetration of water into the treated material.

This process is also becoming common in high end musical instrument manufacture as the timber becomes more acoustically resent.

Thermal modification of Silver Wattle (Acacia dealbata) showing the range of colours achieved, this process allows timber to be used in external applications, making the material highly water resistant. This method of treatment supresses bacterial attack, also reduces the normal expansion and contraction of the treated timbers. The process also stabilises the treated timber reducing in service expansion and contraction.

CAD Drawing through to manufacturing

The process I use to make furniture items some times involves CAD drafting, the ability to get a 3D sketch is use full when making design decisions. My normal process does not replicate the drawing, there are subtle changes that have to be made whilst the making process is under way.